Introduction

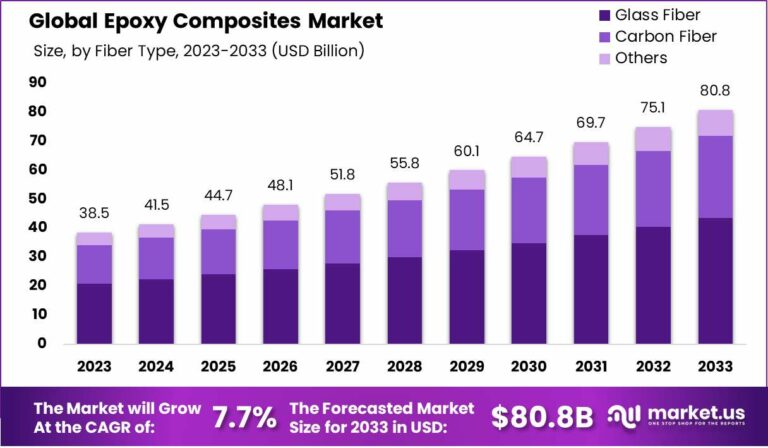

According to Market.us, The global Epoxy Composites Market is poised for robust growth, expected to expand from USD 38.5 Billion in 2023 to an estimated USD 80.8 Billion by 2033, advancing at a compound annual growth rate (CAGR) of 7.7% during the forecast period. This growth is primarily driven by the increasing demand across several key industries including automotive, aerospace, and wind energy, where the need for lightweight, durable, and sustainable materials is paramount.

Epoxy composites are highly regarded for their superior mechanical properties, resistance to environmental factors, and versatility in applications ranging from vehicle manufacturing to wind turbine production. The automotive and transportation sector, in particular, dominates the market use of epoxy composites, leveraging these materials to enhance fuel efficiency and reduce emissions. Similarly, the aerospace and defense sectors rely on epoxy composites for their high strength-to-weight ratios and adaptability to extreme conditions.

Market expansion is further supported by technological advancements in manufacturing processes and a growing emphasis on sustainability. Innovations such as resin infusion and automated layup processes are making epoxy composites more accessible and cost-effective. Additionally, industries are increasingly adopting these materials to comply with stringent environmental regulations that favor low carbon footprints and recyclability.

The global focus on renewable energy, especially wind energy, also catalyzes market growth, with epoxy composites playing a crucial role in the production of larger and more efficient turbine blades. As market opportunities continue to evolve, the epoxy composites industry is expected to see substantial investments and increased adoption across diverse sectors, ensuring its popularity and market penetration on a global scale.

Key Takeaway

- The Global Epoxy Composites Market size is expected to be worth around USD 80.8 Billion by 2033, from USD 38.5 Billion in 2023, growing at a CAGR of 7.7% during the forecast period from 2024 to 2033.

- Glass Fiber dominates the Epoxy Composites Market with a 54.3% share.

- Layup dominated the Epoxy Composites Market with a 28.6% share by manufacturing process.

- Automotive & Transportation led the Epoxy Composites Market with a 33.4% share across diverse industries.

- Asia Pacific dominates the global epoxy composites market with 35%, valued at USD 13.6 billion.

Factors affecting the growth of the Epoxy Composites Market

- Technological Advancements: Innovations in epoxy resin and fiber technologies significantly propel market growth. Improvements in manufacturing processes like resin infusion, which offers reduced waste and higher component quality, are particularly influential. These advancements enhance the performance and application scope of epoxy composites in demanding environments like aerospace, automotive, and wind energy sectors.

- Economic Factors: The market is affected by macroeconomic variables such as interest rates, inflation, and exchange rates. These factors can influence investment in infrastructure and industrial capacities, which in turn impacts the demand for epoxy composites. Additionally, the cost of raw materials, which are often linked to global oil prices, can also affect production costs and pricing strategies within the industry.

- Regulatory Impact: Increasingly stringent environmental regulations drive the adoption of lightweight, durable, and sustainable materials like epoxy composites. These materials are favored in industries under pressure to reduce emissions and enhance energy efficiency, such as automotive and construction. Regulations also guide the recycling and end-of-life disposal of composite materials, further shaping market dynamics.

- Market and Consumer Dynamics: The demand for epoxy composites is also driven by their superior properties, such as high strength-to-weight ratios and resistance to wear and environmental conditions. These attributes make epoxy composites ideal for a range of applications across various industries, including wind energy and aerospace, where their ability to improve energy efficiency and performance is highly valued.

- Challenges and Limitations: The growth of the epoxy composite market faces hurdles such as the availability of close substitutes like other advanced polymers and composites, which can sometimes offer cost or performance advantages depending on the application. Additionally, the complexity and cost of producing high-quality epoxy composites can limit their use to high-value applications unless manufacturing efficiencies can be improved.

Top Trends in the Global Epoxy Composites Market

- Sustainability Focus: There is an increasing emphasis on sustainability within the industry, with companies investing in eco-friendly manufacturing practices. This includes using renewable energy sources, optimizing production to minimize waste, and enhancing the recyclability of products. Such sustainable practices are not only improving the environmental footprint of epoxy composites but also aligning with global regulatory standards and consumer preferences for greener products.

- Advancements in Material Technology: Technological innovations in epoxy resin formulations and composite materials are expanding the applications of epoxy composites. Bio-based epoxy resins derived from renewable sources are being developed, which reduce the carbon footprint associated with their production and use.

- High-Performance Requirements: The demand for lightweight, high-strength, and durable materials is growing, particularly in industries like aerospace, automotive, and wind energy. Epoxy composites are valued for their excellent strength-to-weight ratio, which enables the production of lighter and more fuel-efficient vehicles and aircraft, as well as more effective wind turbine blades.

- Increasing Applications: Epoxy composites are finding increased applications across a variety of sectors including automotive, aerospace, marine, construction, and renewable energy. Their versatility and adaptability make them suitable for a wide range of uses, from structural components to consumer goods.

Market Growth

The global epoxy composites market is experiencing notable growth, projected to accelerate due to increasing demands across various industries for lightweight and durable materials. Epoxy composites are especially valued for their strength-to-weight ratio, making them ideal for sectors like aerospace, automotive, and wind energy, where they contribute to enhanced performance and fuel efficiency.

Additionally, there is a growing trend towards sustainability, which supports the market expansion as industries increasingly adopt eco-friendly materials to meet environmental regulations. Technological advancements are also driving the market, with innovations in material science and manufacturing processes improving the quality and applications of epoxy composites. This confluence of factors is expected to continue propelling the market forward, making epoxy composites a key material in the pursuit of performance and sustainability across global industries.

Regional Analysis

Asia Pacific Rapid industrialization, expanding automotive production, and investments in infrastructure and aerospace dominate the epoxy market, accounting for 35% of the global market. North America is driven by the aerospace and automotive industries, while Europe is bolstered by stringent environmental regulations. The Middle East and Africa show potential for growth, while Latin America is experiencing gradual growth. Asia Pacific’s growth is driven by cost advantages, industrial activities, and government support.

Scope of the Report

| Report Attributes | Details |

| Market Value (2023) | USD 38.5 Billion |

| Forecast Revenue 2033 | USD 80.8 Billion |

| CAGR (2024 to 2033) | 7.7% |

| Asia Pacific Market Share | 35% |

| Base Year | 2023 |

| Historic Period | 2020 to 2022 |

| Forecast Year | 2024 to 2033 |

Market Drivers

The market for epoxy composites is gaining momentum due to the increasing demand in the wind energy sector, automotive production, aerospace and defense applications, and technological advancements in manufacturing. The wind energy sector is a leading sector due to its high strength-to-weight ratio and durability, which is crucial for producing larger blades. The automotive industry’s shift towards lightweight and fuel-efficient vehicles is also driving the demand for epoxy composites.

The aerospace sector’s expansion and increased defense spending are also driving the demand for high-performance materials. The high mechanical strength and durability of epoxy composites make them desirable across various industries. Technological advancements in manufacturing processes, such as automated lay-up technology and 3D printing, have streamlined production and made epoxy composites more accessible, enhancing their performance and potential applications.

Market Restraints

The epoxy composites market is influenced by raw material price volatility, which can lead to unpredictable production costs and hinder market expansion. High production costs, exacerbated by complex manufacturing processes and specialized equipment, reduce profit margins and make the market less attractive to new entrants. Supply chain disruptions, such as logistical challenges or pandemics, can stifle growth by causing delays in raw material procurement and distribution.

Longitudinal research and development processes can also slow time-to-market, impacting manufacturers’ competitive edge. Delays in R&D can result in missed opportunities and reduced market share, as competitors may accelerate their own innovations.

Opportunities

The global epoxy composites market is experiencing significant growth due to the integration of carbon fiber in industries like aerospace, automotive, and sports equipment. Carbon fiber’s high stiffness, tensile strength, and low weight make it attractive for advanced applications. Sustainability initiatives are also driving market expansion, as manufacturers focus on sustainable epoxy resin formulations.

The increasing demand for renewable energy sources, particularly wind energy, is driving the market’s expansion. Technological advancements in processing and fabrication are also enhancing the market’s potential, making it more accessible for a wider range of applications.

Report Segmentation of the Epoxy Composites Market

By Fiber Type Analysis

Glass Fiber dominates the Epoxy Composites Market with 54.3% share in 2023, due to its superior properties like strength, flexibility, durability, and cost-effectiveness. It is widely used in industries like automotive, aerospace, and construction. Carbon Fiber, known for its stiffness and high-temperature tolerance, also holds a significant share. Other materials like aramid and natural fibers cater to niche market needs with specialized performance characteristics.

By Manufacturing Process Analysis

Layup holds a 28.6% market share in the Epoxy Composites Market, primarily due to its simplicity and cost-effectiveness. Compression Molding, resin injection molding, resin transfer molding, and filament winding are other methods used in the industry. Resin injection molding is efficient for high-volume production, while resin transfer molding is used for complex geometries and surface finishes. Fabrication winding creates cylindrical shapes, while pultrusion produces continuous composite material for construction and infrastructure projects. Other methods contribute to the market’s diversity and adaptability, each chosen based on the desired properties and application area.

By End-use Analysis

The Automotive & Transportation sector dominates the Epoxy Composites Market with 33.4% share in 2023, driven by the need for lightweight, durable materials in vehicle manufacturing. The aerospace & defense sector also uses epoxy composites for aircraft components and military equipment. Wind energy uses epoxy composites for wind turbine blades, while electrical & electronics use them for insulators and transformers. Sports & Consumer Goods use them for golf clubs, bicycles, and rackets. Construction and marine industries also use epoxy composites for corrosion resistance and structural strength.

Recent Development of the Epoxy Composites Market

In order to meet the growing demand for epoxy composites in industrial and aerospace applications, Hexcel Corporation stated in April 2023 that it would be expanding its capacity to produce carbon fiber in France.

The Epsilon Composite revealed a major technological breakthrough in CFRP pull winding and pultrusion processes in February 2023. The need for high-performance epoxy composites in a range of industrial applications is anticipated to increase as a result of this improvement.

Competitive Landscape

The competitive landscape of the global epoxy composites market is dynamic and features a range of major players who significantly contribute to the industry’s development. These companies include Arkema, Avient Corp., Axiom Materials, Barrday, Hexcel Corp., Huntsman Corp. LLC, Mitsubishi Chemical Corporation, Olin Corp., Park Aerospace Corp, Sanders Composites, SGL Carbon, Solvay, Teijin Carbon Europe GmbH, Toray Industries, Inc., and Veplas d.d. These competitors are engaged in fierce competition and innovation, focusing on expanding their market reach and enhancing their product offerings.

Several of these companies are leaders in advanced material technologies, specializing in the production and development of high-performance epoxy composites used across various sectors such as aerospace, automotive, sports, electronics, and construction. For instance, Toray Industries, Inc. and Teijin Carbon Europe GmbH are well-known for their contributions to aerospace and automotive sectors, providing materials that help in reducing weight and increasing efficiency.

Innovation and strategic partnerships are common among these players, aiming to leverage new technologies and expand into new markets. For example, Hexcel Corp. and Mitsubishi Chemical Corporation are heavily invested in research and development to produce more sustainable and efficient composite solutions. Similarly, companies like Solvay and Arkema focus on developing eco-friendly composites that comply with global environmental regulations, enhancing their appeal in industries prioritizing sustainability.